Laser Processing of Innovative Lightweights

Carbon fiber reinforced polymer (CFRP) are modern materials increasingly used by aircraft manufacturers and automakers for their unique properties (strength, stiffness, insulation, low density, corrosion resistance). However, these many properties also significantly complicate the processing of such materials.

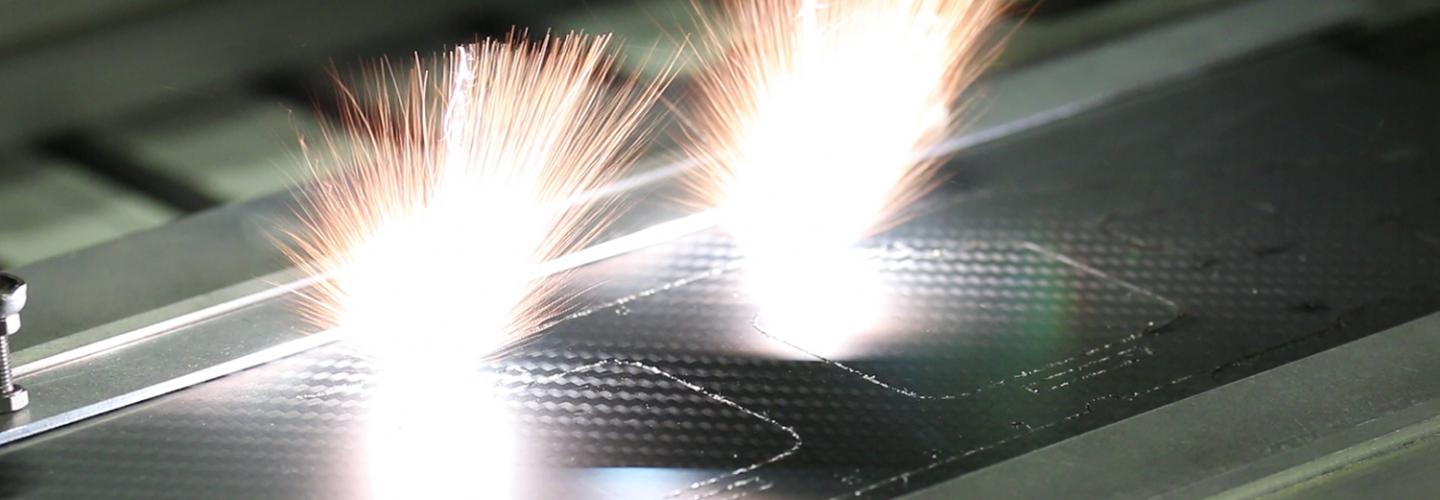

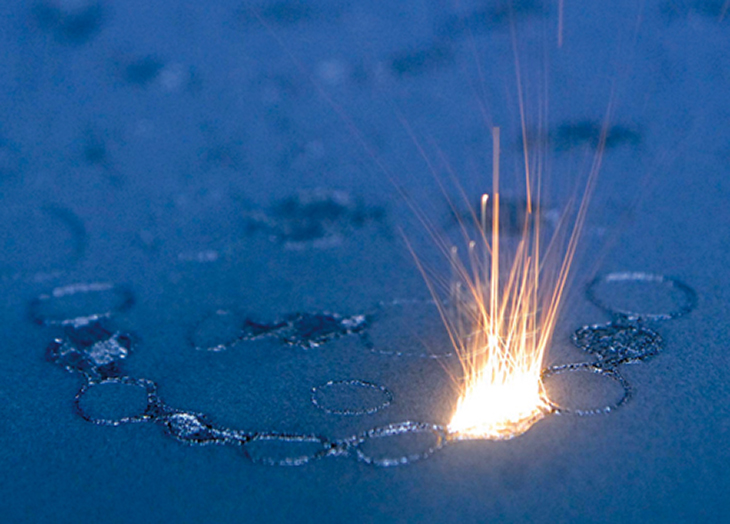

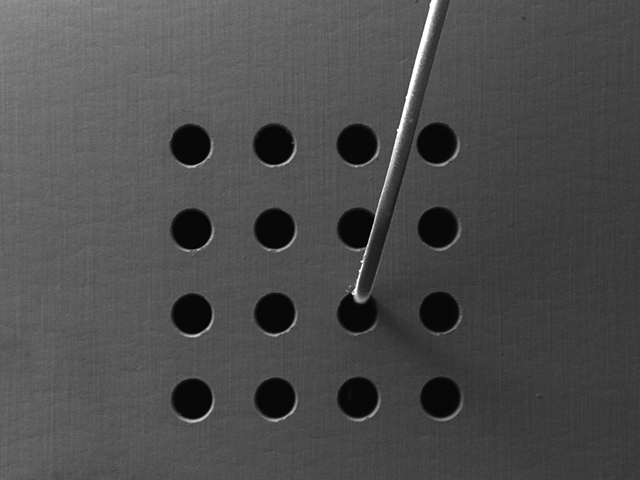

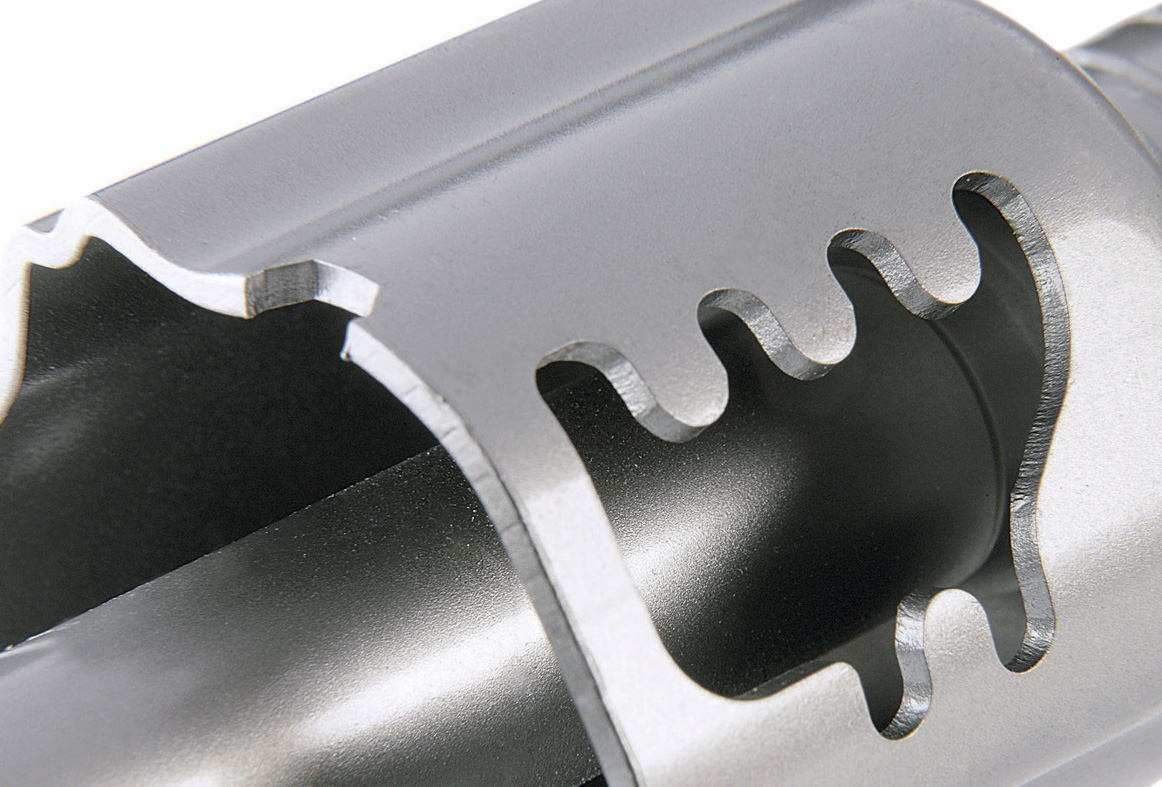

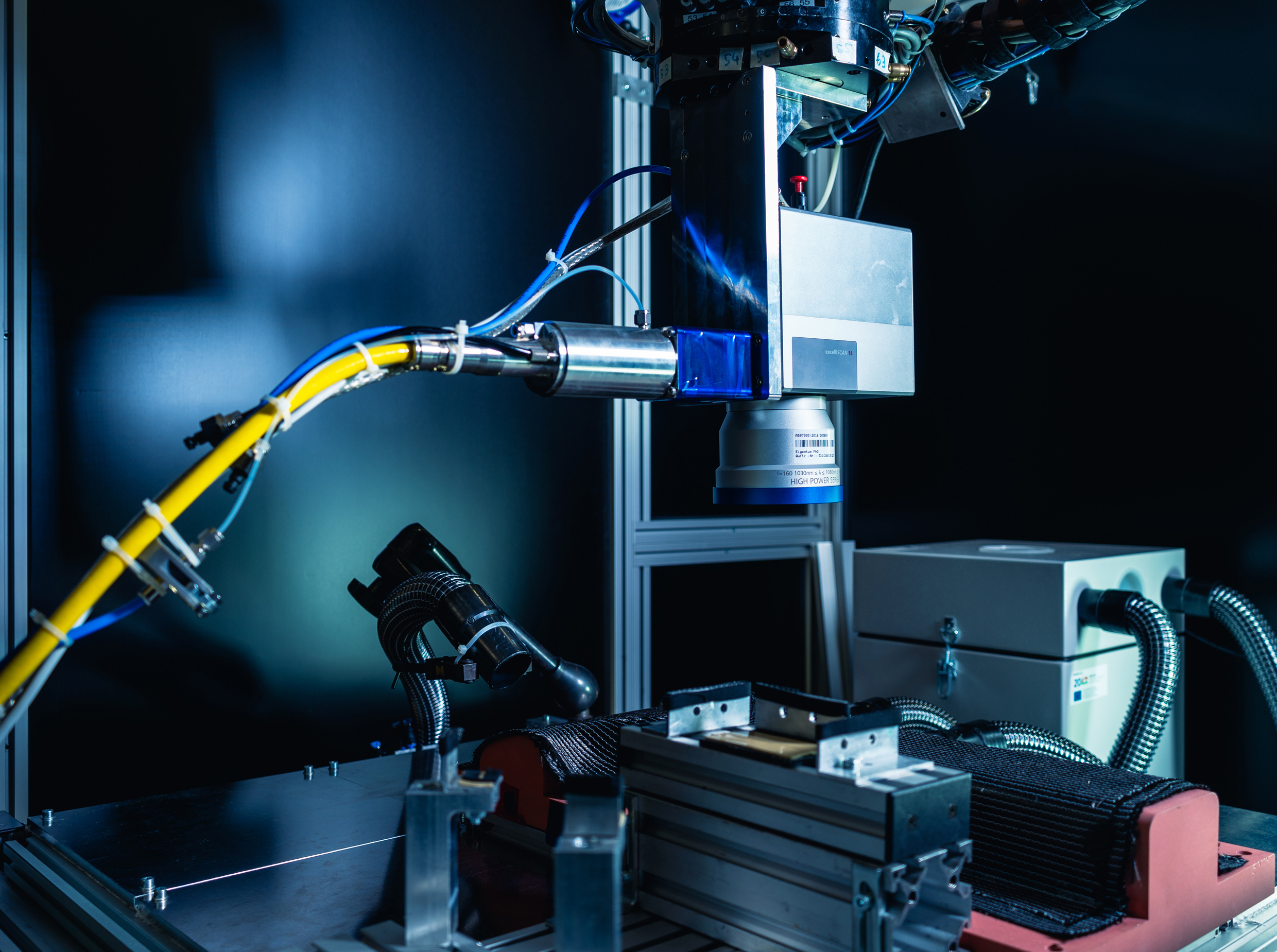

Laser systems offer numerous solutions for efficient and nondestructive CFRP material processing. Laser processes enable drilling, cutting, and preparation of CFRP surfaces for bonding. Even direct welding is possible. Here, material processing must generate as little heat as possible, to prevent damage, wear and tear.

Typical Laser Processing Methods

-

Laser cutting quick and precise cutting of freeform surfaces – also in conjunction with industrial axes and robot systems

-

Laser milling ultra-precise, fast and reproducible milling – wear-free, because it's tool-free

-

Laser marking contactless marking of materials, e.g. for batch tracking

-

Repairing damage targeted removal of damaged CFRP areas

-

Laser welding weld preparation and durable bonding

Research Collaboration

HyBriLight (2014-2018)

Material-optimized process chain for cost-efficient composite lightweight construction with high-productivity laser systems

Background Article

Lasers as Tools

By transforming lasers into universal tools, scanning solutions help to add functionality and value to materials. SCANLAB's broad palette of scanning solutions fulfills demands for higher speed, more precision, greater efficiency or improved environmental compatibility.