Lasers Make Cars Better

The automotive industry faces countless challenges around the world, such as: lighter, safer, smarter, environmentally friendlier. Laser processes deliver exceptional flexibility with high robustness, and meet tough safety standards.

Laser Tools Offer

- Increased productivity

- Further enhancement with trajectory planning

- Material and weight savings

- Enhanced sustainability thanks to lower fuel consumption

- Greater safety

- More design flexibility

- More process monitoring for higher product quality

Typical Laser Scan Applications in the Automotive Industry

- Remote welding of body components and heat exchangers, for further information visit the website of our associated company Blackbird Robotersysteme GmbH.

- Welding of plastics e.g. contactless welding of containers or headlights

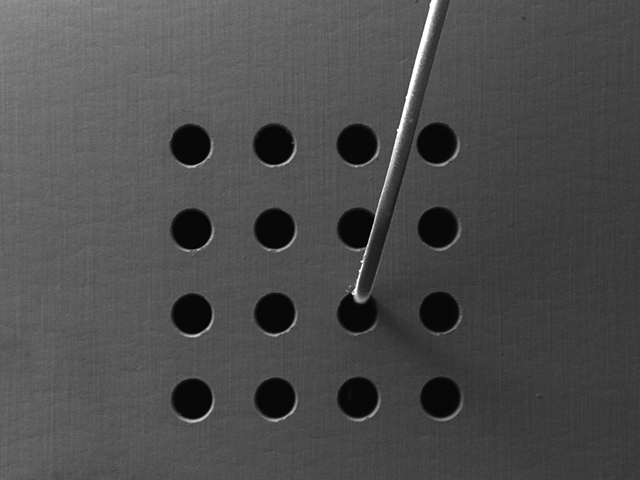

- Laser drilling for micrometer-exact fabrication of injection nozzles etc.

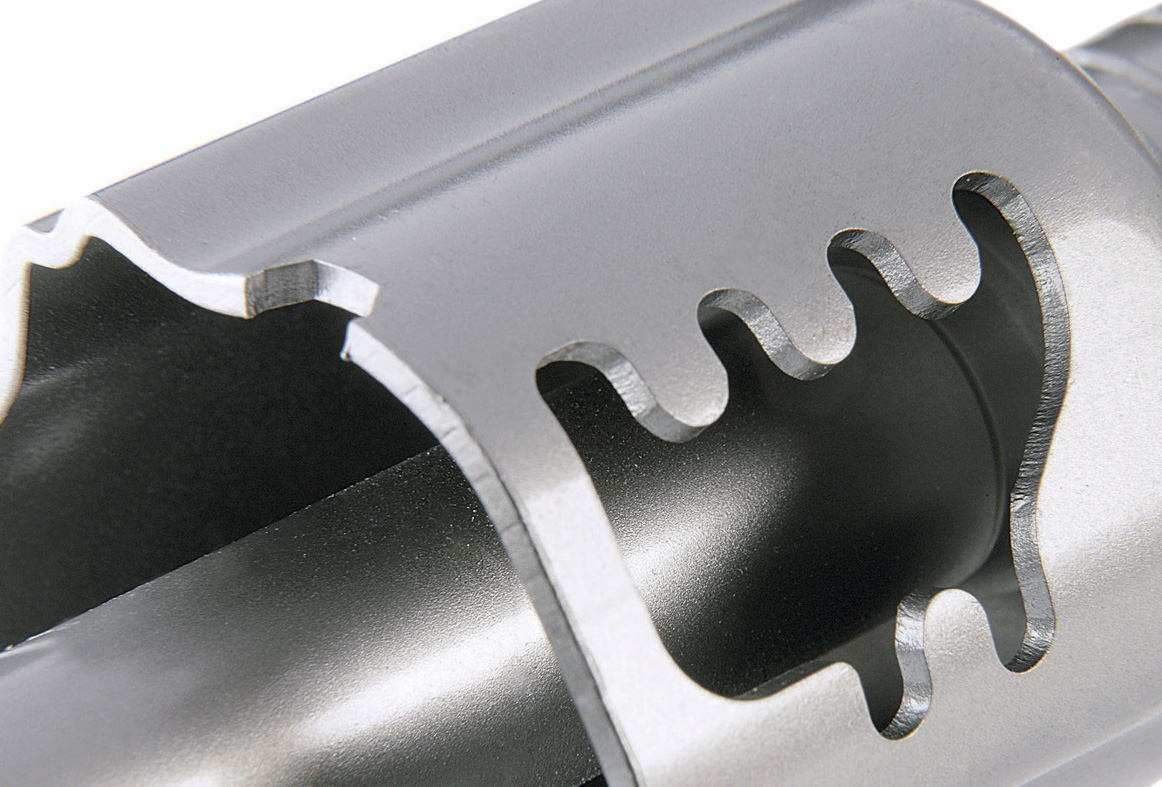

- Laser cutting of installable parts, airbags and other technical textiles (e.g. CFRP)

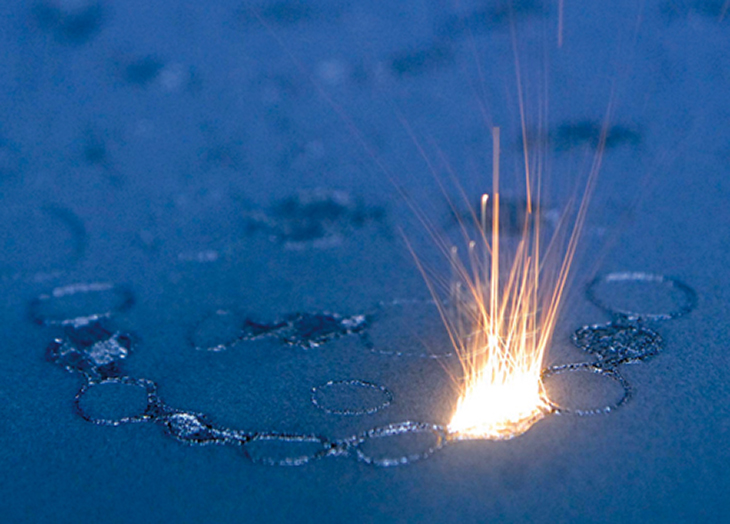

- Laser hardening of highly stress-subjected mechanisms for minimized wear and tear

- Laser perforation e.g. for defined breaking points in airbag fittings

- Laser structuring for surface treatment, minimizing friction losses, and tool mould making for interior fitting components

- Laser marking day/night labeling of displays or controls, laser marking of nameplates, laser labeling of parts for batch tracking

- Functionalizing via laser cleaning processes for preparation of bonding surfaces, paint removal, degreasing, creating oxide layers etc.

- Additive manufacturing for example for customized component manufacturing

Research Collaborations

eVerest (2016-2018)

Machines and system technology for efficiently fabricating large 3D mold tools with design surfaces

HyBriLight (2014-2018)

Material-optimized process chain for cost-efficient composite lightweight construction with high-productivity laser systems

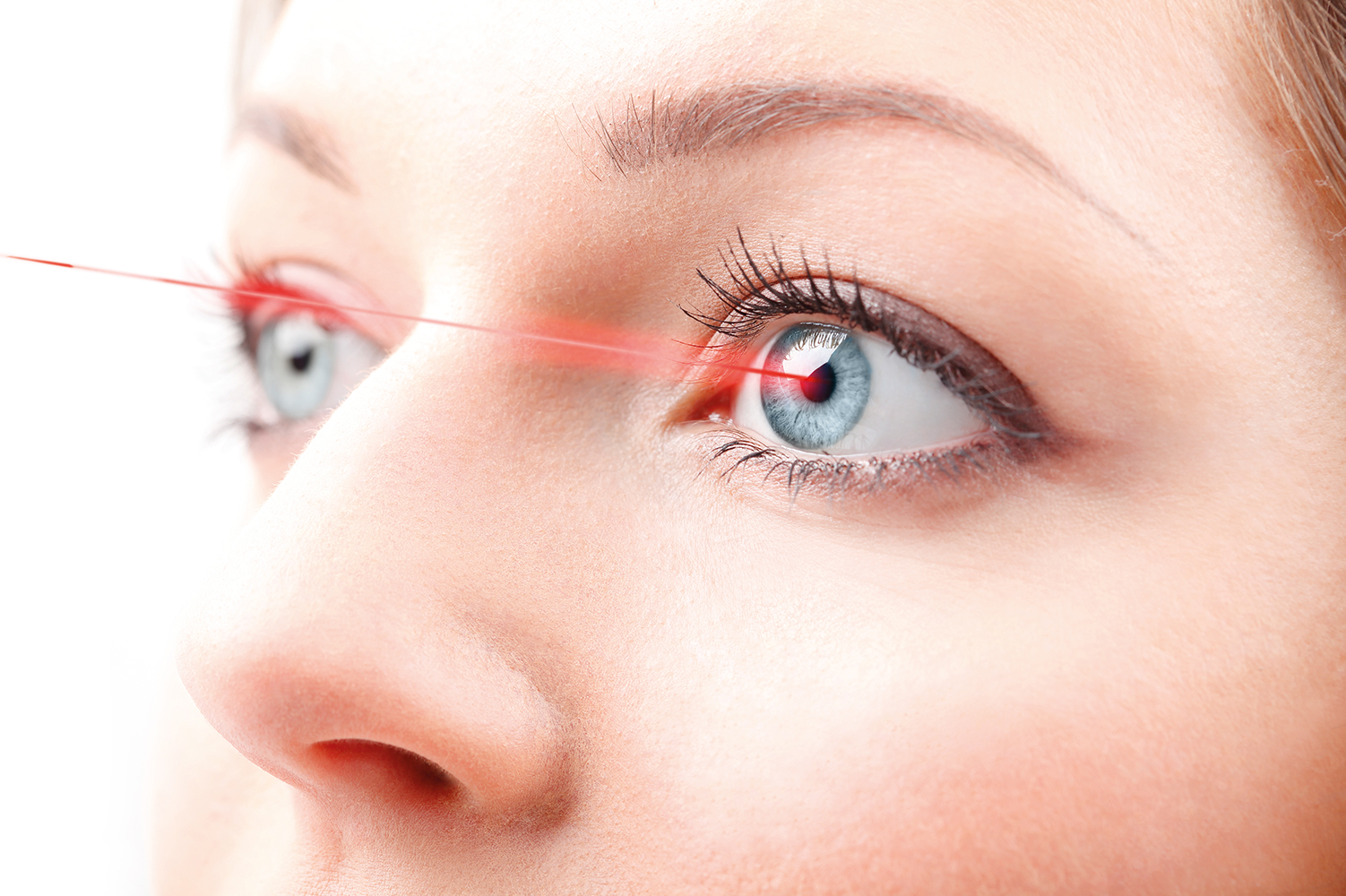

Lasers as Tools

By transforming lasers into universal tools, scanning solutions help to add functionality and value to materials. SCANLAB's broad palette of scanning solutions fulfills demands for higher speed, more precision, greater efficiency or improved environmental compatibility.