Highest Accuracy for Large-Surface Micromachining

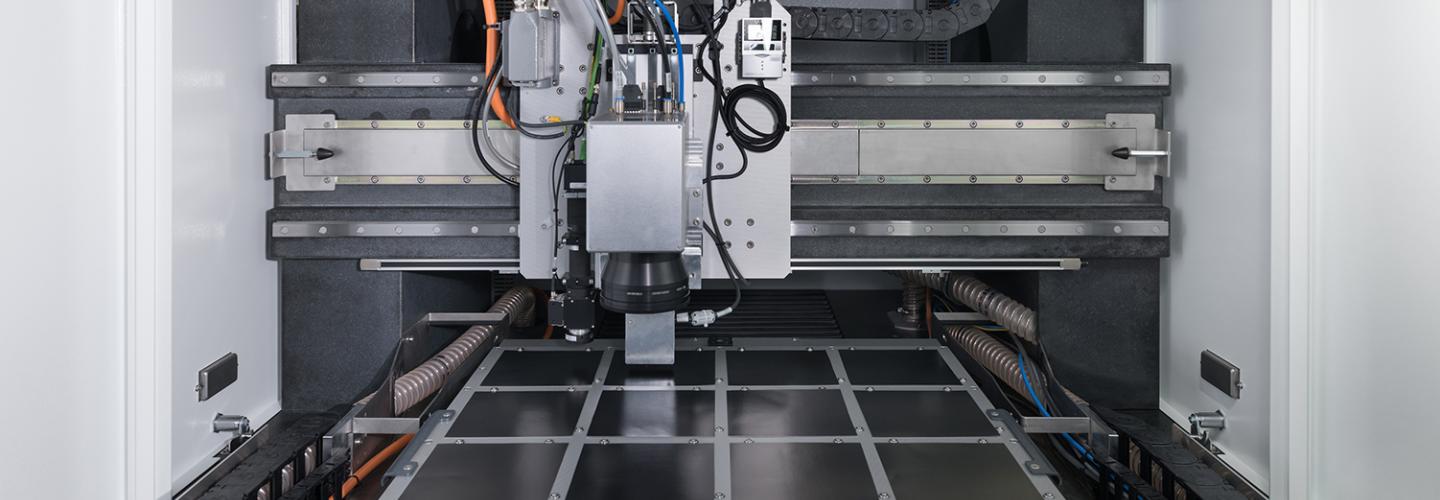

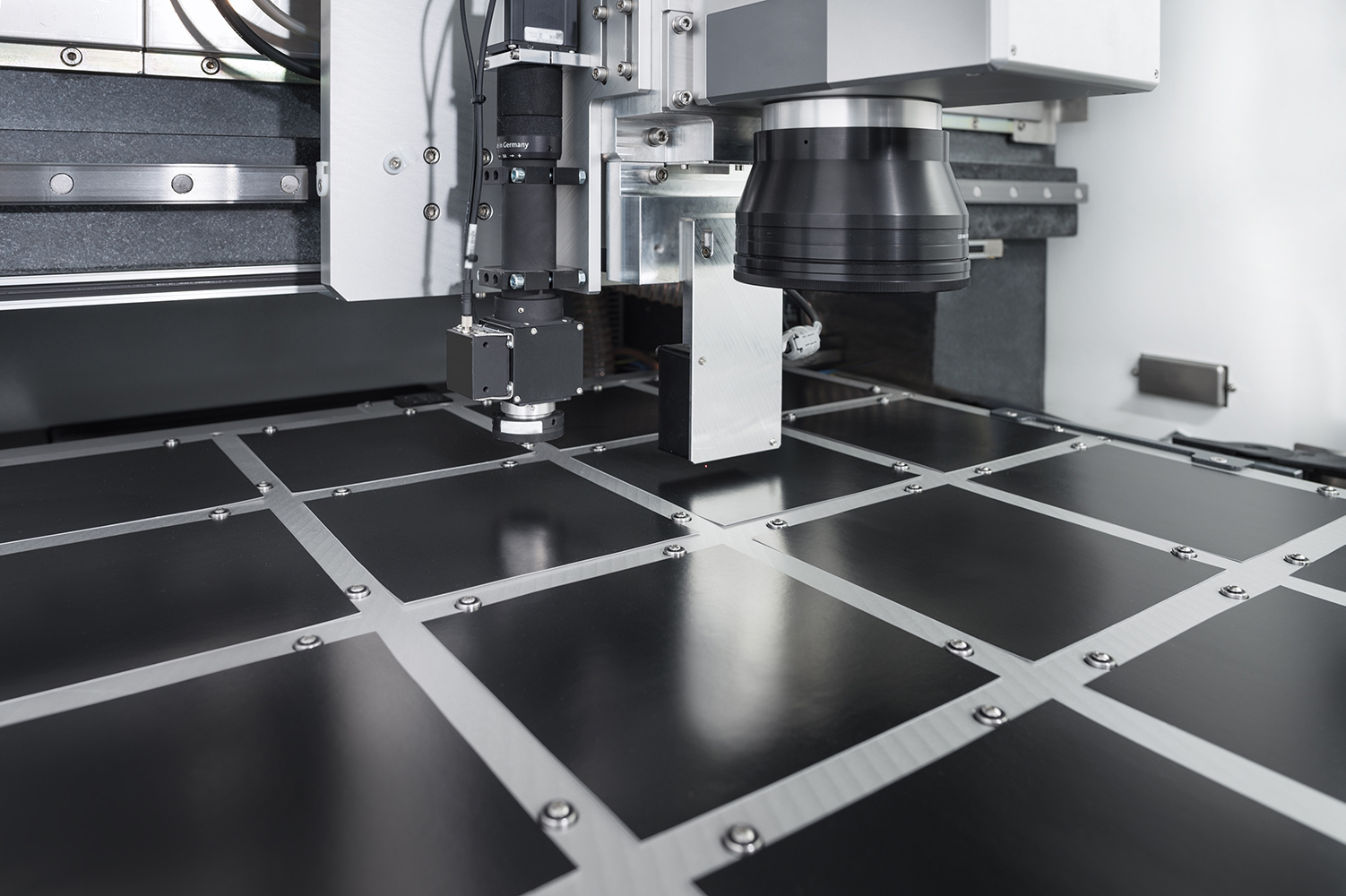

XL SCAN is a scan solution for synchronously controlling a 2D scan head and two mechanical axes, for example an XY stage with two servo axes. The system was co-developed by SCANLAB and ACS Motion Control and provides a virtually limitless working area.

XL SCAN is ideally suited not only to micromachining of extensive areas, but also for cutting large films and drilling PCBs in electronics manufacturing.

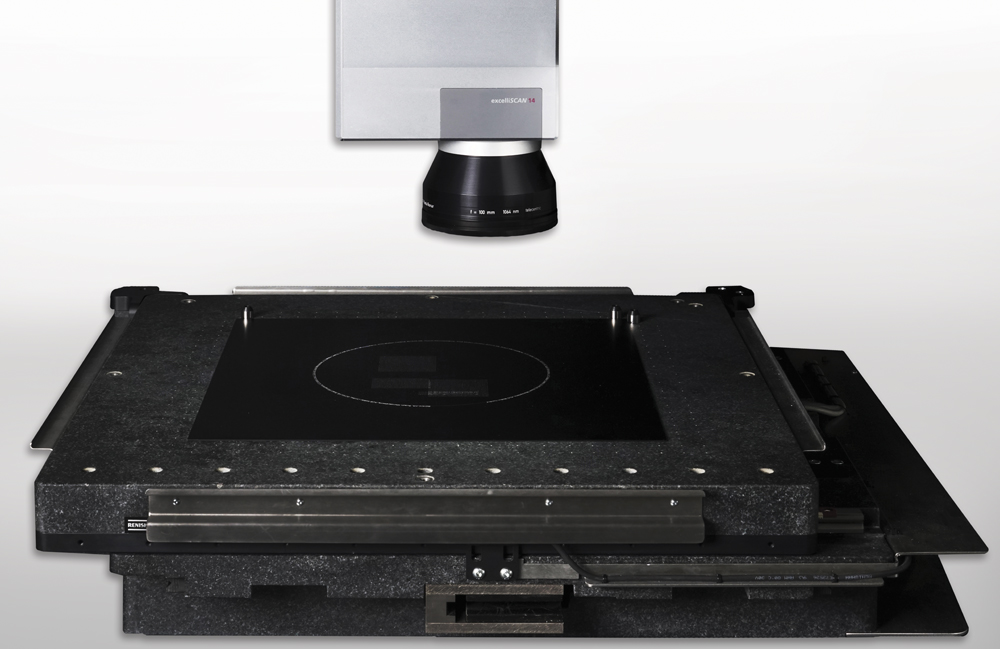

Moreover, the use of tracking-error-free excelliSCAN scan heads and smart syncAXIS software assures highest precision for the application.

Key Features

- Virtually limitless working area

- Highest accuracy

- No stitching errors

- Increased productivity

- Simulation of jobs makes laser process optimization easy

- Automatic laser control, e.g. Spot Distance Control (SDC)

- Highly dynamic processing without stage vibration

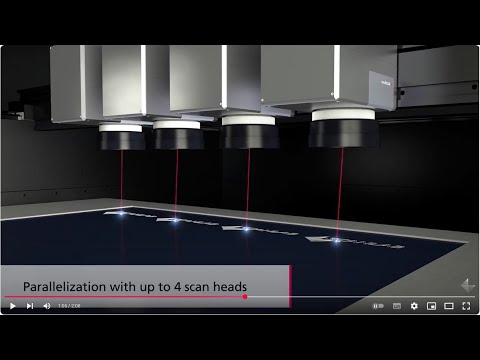

- Flexible configuration possibilities (e.g. multi-head systems, multiple software instances)

Throughput Optimization

XL SCAN's contributors to enormously boosted throughput include optimized control and servo mechanisms – such as synchronous control or look-ahead trajectory planning – as well as the possibility of multi-head systems.

Highest Accuracy

This synchronized scan solution avoids stitching errors and compensates workpiece vibration. The totally new smart control approach considers the physical limits of table and scan head in trajectory planning. XL SCAN's precision thereby exceeds that of other combined-control systems on the market.

Additionally, the syncAXIS control software's trajectory planning supports advanced control of modern ultra-short pulse (USP) lasers.

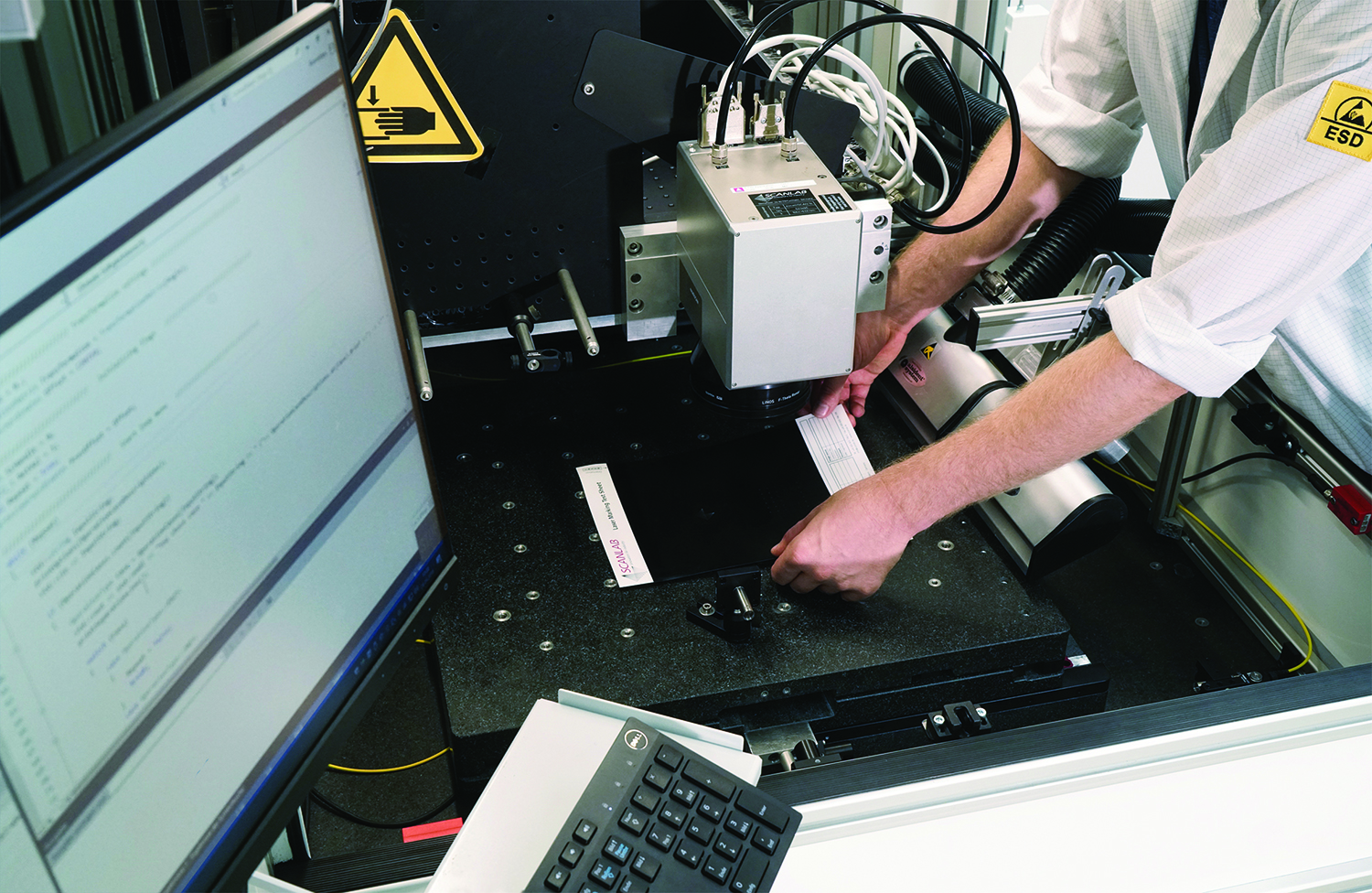

User-friendly syncAXIS Control Software

syncAXIS control's operating interface allows fast and intuitive creation of user programs for XL SCAN.

Furthermore, the software offers a simulation mode for simplified process definition, as well as a syncAXIS Viewer to display and evaluate simulation results. Also integrated are features that streamline program development and provide straightforward and efficient debugging.

SCANmotionStudio: Faster Integration

SCANmotioStudio is a software with which laser jobs for the XL SCAN can be created, simulated and executed without any programming effort. It allows laser micromachining equipment manufacturers to bring complex machine concepts to market faster.

Benefits of SCANmotionStudio

- Software-supported system configuration of axis and scanner

- Import and preparation of CAD data

- Comfortable job definition and execution control makes SCANmotionStudio the ideal tool for integration into automation concepts

- You as a user speed up system evaluation and design

XL SCAN

Simultaneous Laser Processing in Practice

XL SCAN with Smart Processing Commander (SPC)

Fast integration into laser machine concepts