Innovative Scanner Control

SCANahead is an innovative scanner control technology of laser scan systems to improve dynamics and precision.

Advantages

- Increase in productivity due to significantly shorter acceleration phases without tracking error

- Fast marking of circles without necking effects

- Auto delay function of the RTC6: Laser and scanner delays are set automatically

Principle

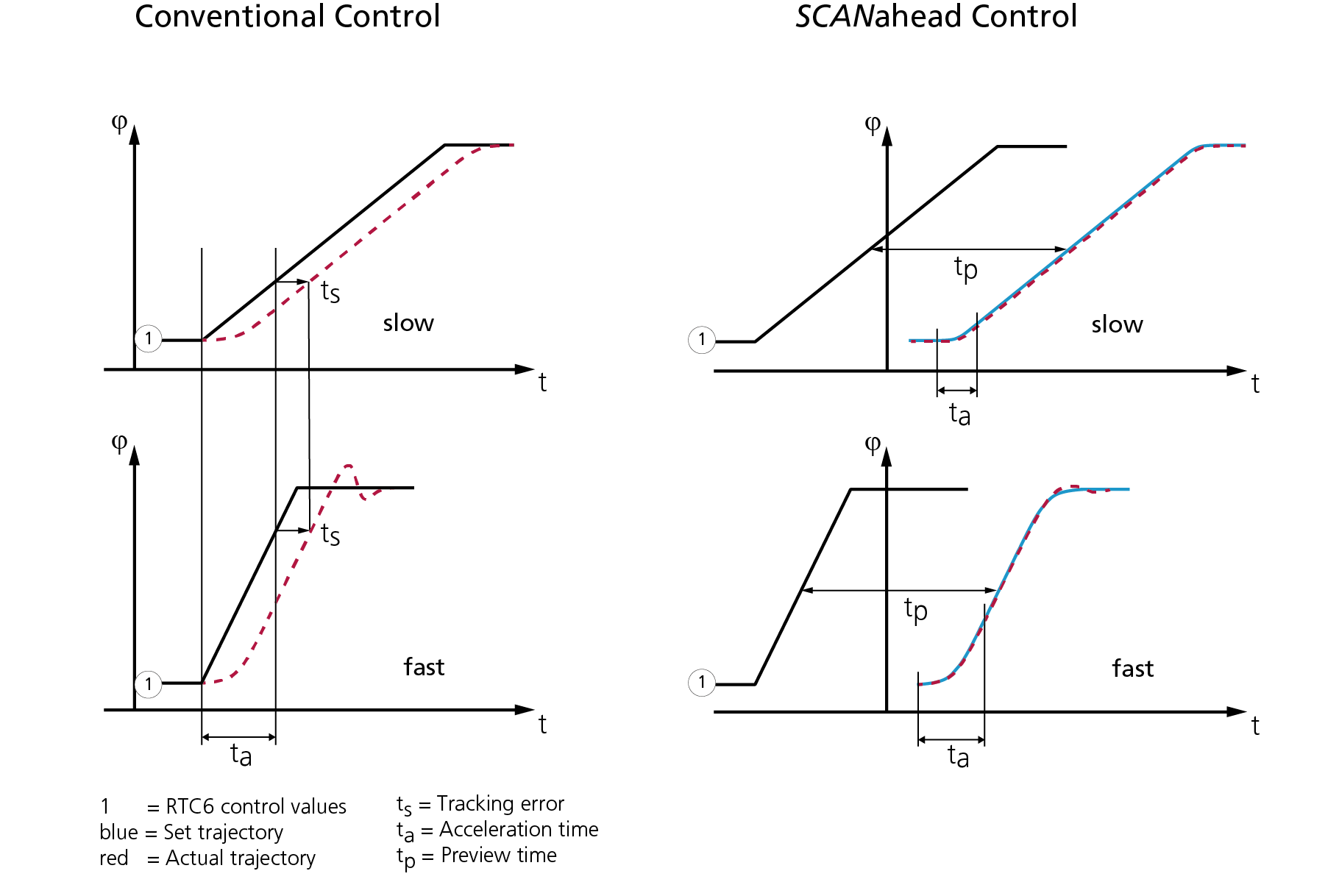

Scan systems with SCANahead control always accelerate to the maximum (i.e. in the minimum acceleration time ta). In contrast to the conventional control with tracking error ts which have a constant acceleration time regardless of the target speed, scan systems with SCANahead control require suitably generated control values, for example with an RTC6 control board.

RTC control boards with SCANahead function generates suitable control values with automatically determined delays for each scan system. Limiting the acceleration of the target path to the maximum acceleration of the scanner axes in the scan head (blue line) ensures that the dynamic potential of the galvos is fully utilized.

The calculation is performed in real time – the execution of the movement is accordingly offset by the preview time tp.

SCANahead Control Compared to Conventional Control

| Conventional Control | SCANahead Control | |

| Dynamics |

|

|

| Tracking error [ts] |

|

|

| Use of delays |

|

|

| Example application: Circles and arcs (Circle: v = 2.8 m/s) |

|

|

| Example application: 90° corners (Corner: v = 1 m/s) |

|

|

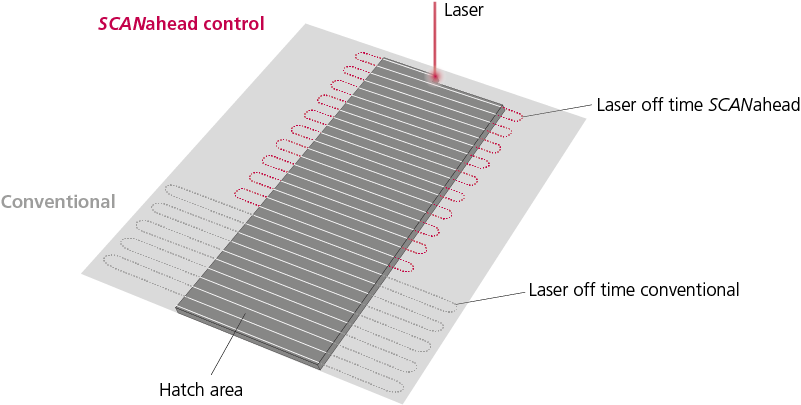

Example 3D Printing

In additive manufacturing, two-dimensional structures are typically realized by bidirectional hatching. A large part of the process time in scan systems with conventional control is required for the turnaround times for acceleration and deceleration processes.

Scan systems with SCANahead control significantly reduce these turnaround times and therefore contribute to a significant increase in productivity.

Products with SCANahead

The following scan systems support SCANahead:

excelliSCAN

|

intelliSCAN IV

|

fiberSYS

|